As a global leader in certification, Bureau Veritas has chosen SmartShape to digitize its ship classification process. The multiple back-and-forths with design offices are a thing of the past; the certification body now performs ship classification based on a single 3D model.

Bureau Veritas: A Global Player in Certification

Founded in 1928, Bureau Veritas (BV) is a company specializing in testing, inspection, audit, and certification. It operates across numerous sectors such as agri-food and agriculture, infrastructure and construction, health, raw materials, energy, and shipbuilding.

With a presence in 140 countries, BV has 84,000 employees, of which 2,600 work in the Marine & Offshore activity. Their role is to ensure the compliance of ships (both under construction and in service), offshore platforms and units, as well as maritime equipment.

BV Marine & Offshore contributes to safety at sea and provides technical expertise to assess and manage risks and improve the performance of its clients.

Addressing the Challenge of Information Sharing in the Classification Process: The Case of Chantiers de l’Atlantique

BV Marine & Offshore assists the design offices of Chantiers de l’Atlantique in the classification (design verification) of its marine assets. The key outcome is the acquisition of operating licenses for these assets and the assurance of their operational efficiency and compliance with international regulations.

This phase is critical as the consequences of poor ship design can be severe: high operating costs, reduced operational lifespan, accident risks, etc. That’s why stakeholders in this type of project (builder, shipowner, insurer, etc.) trust BV’s expertise to guarantee the quality of the ships.

As part of the classification process for ships under construction, Bureau Veritas experts are tasked with analyzing plans designed by naval construction engineers. However, the complexity of these projects places the issue of information sharing at the heart of the classification process.

Optimizing the Classification Process (Design Verification)

The classification process mainly relies on the review conducted by experts during the design and shipbuilding phases. Before using SmartShape, BV operated through an iterative loop process with Chantiers de l’Atlantique:

- The shipyard’s design offices produce their 3D models in CAD.

- These 3D models are converted into 2D blueprints and transmitted to BV.

- BV performs its analyses and calculations and then sends the updated blueprints back to the design offices.

- The design offices produce new 3D models.

- These new models are in turn converted into 2D blueprints and sent back to BV for analysis.

- Etc.

This process is particularly lengthy since it involves producing new versions of the documents (3D models and 2D plans) at each step. Moreover, this abundance of documents requires ensuring that every project participant has access to the correct version of the document, which mechanically increases the risk of errors due to poor synchronization.

The adoption of SmartShape has enabled Bureau Veritas Marine & Offshore and the Chantiers de l’Atlantique to rethink information sharing and to radically simplify the classification process by carrying out all operations on a single 3D model.

Perform classification on a single 3D model

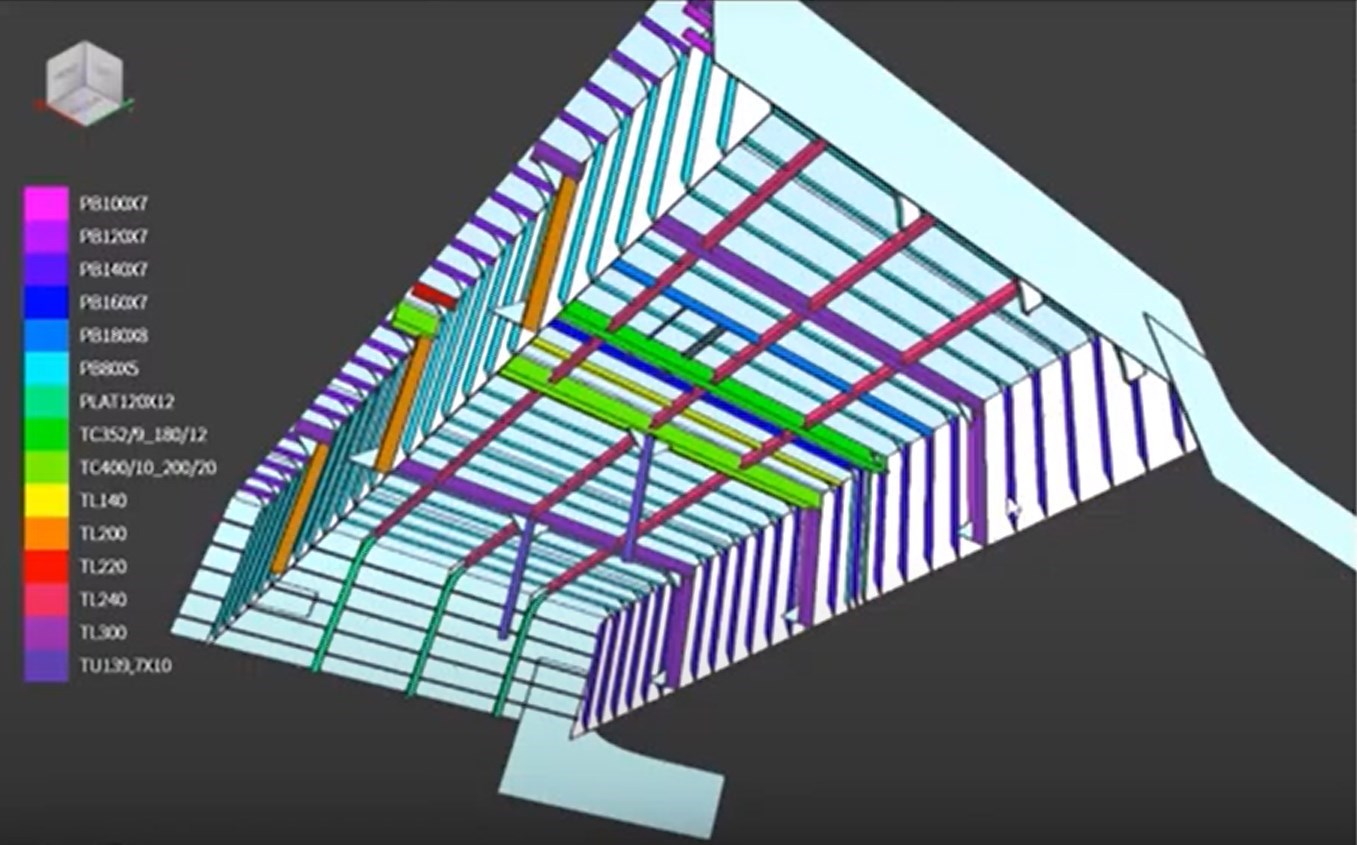

Bureau Veritas is the first classification society to do away with 2D plans. With SmartShape, the classification process is conducted directly on the 3D model: all experts – regardless of their discipline – work on the same model at the same time.

BV Marine Offshore performs its calculations and analyses directly on the 3D model designed by the Chantiers de l’Atlantique. The fact that there is no need to generate a blueprint significantly speeds up the process, both for the shipyard and for BV.

Furthermore, SmartShape serves as a unique, persistent repository that aggregates all project data in real-time. BV and its clients share a single source of truth, which improves product quality by avoiding the inconsistencies inherent in multiple drawing revisions.

Optimize collaborative work on the 3D model

Working on a unique 3D model facilitates collaboration between BV experts and its clients, taking into account existing tools and processes.

A universal solution and a custom configuration

SmartShape has adapted to the specificities of the IT ecosystem of Bureau Veritas, especially in terms of collaboration and document management. In this case, it was essential to link SmartShape to its Document Management System (DMS) which is not designed for 3D plan visualization.

SmartShape has configured and integrated the tool so that BV can use the 3D model and its DMS software in parallel. Experts can thus easily communicate information to clients, who view the comments directly on the 3D model.

“The use of the 3D model improves the quality of data and exchange with our clients. Thanks to this, we save time and enhance the sharing of information among the various project stakeholders. On the shipyard side, the classification process avoids the generation of 2D plans and thus reduces the workload of the shipyard and the associated costs.” According to Olivier Degrand, Naval and Offshore Structural Engineer at Bureau Veritas.

In its approach to 3D classification, Bureau Veritas introduces a new concept called “BV Classification Status,” which indicates for each element, the progress of the design review in real time. With the color code in the SmartShape viewer, designers or shipyards can easily identify whether the design complies with Bureau Veritas rules or not.

SmartShape: a solution dedicated to industry stakeholders

SmartShape enhances information sharing and collaborative work efficiency by combining 3D modeling, collaborative platform, and digital twin technologies.

SmartShape meets the specific needs of industrial enterprises:

- A self-hosted solution that combines the agility of SaaS with the security of On-premise environments.

- A universal and customizable solution: SmartShape supports over 50 file formats in 2D and 3D (both standard and proprietary) and integrates with all IT environments. Its open API (with over 75 endpoints) allows you to program the platform according to your needs (files, configuration, attributes, etc.). Furthermore, the SmartShape 3D engine is open source, ensuring transparency and benefiting the longevity and security of your project.

- A 3D model incorporating all data produced by project participants via the SmartShape API (3D files, 2D blueprints, photogrammetry, point clouds, Excel, etc.). The assembly of this information forms the shape of your project. During the operational phase, data captured on the asset is transmitted to the model, turning it into a true digital twin.

- A tool that integrates all your business processes (plan review, quality, progress, testing, etc.) to add a layer of intelligence (smart) to your model.

- A real-time collaborative platform: when annotations or enhancements are made to the model, all teams have immediate access.

- An offline mode for accessing sometimes very large 3D models in environments without internet access (e.g., within the metal structure of a ship or in the basements of an infrastructure).

- Military-grade encryption to protect sensitive data.

- Support throughout your engineering project by a team of experts.

With SmartShape, Bureau Veritas has profoundly transformed its classification process by simplifying information flows with Chantiers de l’Atlantique. The time savings and quality improvements benefit everyone, throughout the life cycle of the ships.

This leap forward made by major industry players attests to the relevance of SmartShape in meeting the challenges of information sharing in industrial projects.

Better understand the possibilities of SmartShape?

Schedule a demo