The management of sewage networks is a vital activity for society. The operation, maintenance, and upkeep of these critical infrastructures engage about 35,000 workers in France: sewer workers, electromechanics, hydraulicians, electrotechnicians, cleaning specialists, engineering offices, surveyors, inspectors, etc. When working in sewers, these individuals are exposed to significant health risks (falls, drownings, respiratory distress, etc.).

To reduce these risks and improve the management of its sewage networks, the City of Paris has undertaken, through a public contract, to model in 3D more than 40 km of galleries (which is ⅙ of the network). As part of this tender, the company SEMERU – a subsidiary of the FAYAT group – and SmartShape have demonstrated the possibilities offered by 3D modeling and digital twin technology. We reveal the behind-the-scenes of this project in the service of the public interest.

SEMERU: Technological Innovation at the Service of Society

A subsidiary of the energy branch of the Fayat group, the company SEMERU specializes in the development and integration of digital solutions and brings its expertise in several areas:

- Environment: design, integration & maintenance of systems

- Connected building: security & networks, IoT, supervision

- Facility Management Technology: management of general services

- Transport: technological & sustainable vision of people mobility

- Smart City: management of technologies & control of flows

Acquisition, processing, and use of 3D data from the sewage network

The public tender opened by the City of Paris was related to the acquisition, processing, and use of 3D data for the Parisian sewer network. To demonstrate the relevance of its solution, SEMERU undertook the modeling of a part of the Paris sewers. To do this, it started by sending an acquisition team comprised of individuals all holding the CATEC certification (certificate of aptitude for working in confined spaces).

On the day of the intervention, after verifying on dedicated software that there was no lockout on the network, and after securing the perimeter on the surface, the team descended into the galleries with the acquisition equipment and progressed through the network to take a large quantity of photos. This is what photogrammetry entails, a technique allowing for the 3D digital modeling of an object or place.

As it progresses, the team conducts further measurements – including planimetry and altimetry – to locate the shots in space.

Photogrammetry: A Technique for 3D Modeling

Photogrammetry is a measurement technique consisting of determining the shape, dimensions, and position of an object in space from multiple images taken from different angles.

Mimicking human stereoscopic vision, it uses parallax, which is the difference between the viewpoints of the images, to reconstruct the relief of the scene or object. With technological evolution, this method has adapted to digital images, making possible a faithful 3D modeling of reality. This accuracy is achieved through rigorous modeling of the geometry of the images and their acquisition.

Reconstruction of a 3D model of sewers and a wastewater treatment plant in SmartShape

Once the on-site intervention is completed, SEMERU processes the photos and aligns them so that they are correctly positioned and georeferenced. After verification, it is finally possible to launch the production of the high-resolution meshed 3D model with SmartShape.

In parallel, SmartShape has integrated the 3D data of a wastewater treatment plant managed by Suez and connected to the network modeled by SEMERU. The created model results from the hybridization of two modeling techniques: photogrammetry for the sewer network (over 400 km) and 3D scanning for the wastewater treatment plant.

Simplify and secure on-site interventions with SmartShape

The solution proposed by SEMERU and SmartShape greatly simplifies interventions. Indeed, the 3D model incorporating part of the sewer network as well as a wastewater treatment plant allows all stakeholders to carry out virtual tours of the structures to visualize the equipment in place and move around in the collectors.

The ability to virtually visit the sewers is enhanced by collaborative features developed by SmartShape, allowing maintenance teams to safely prepare their on-site interventions.

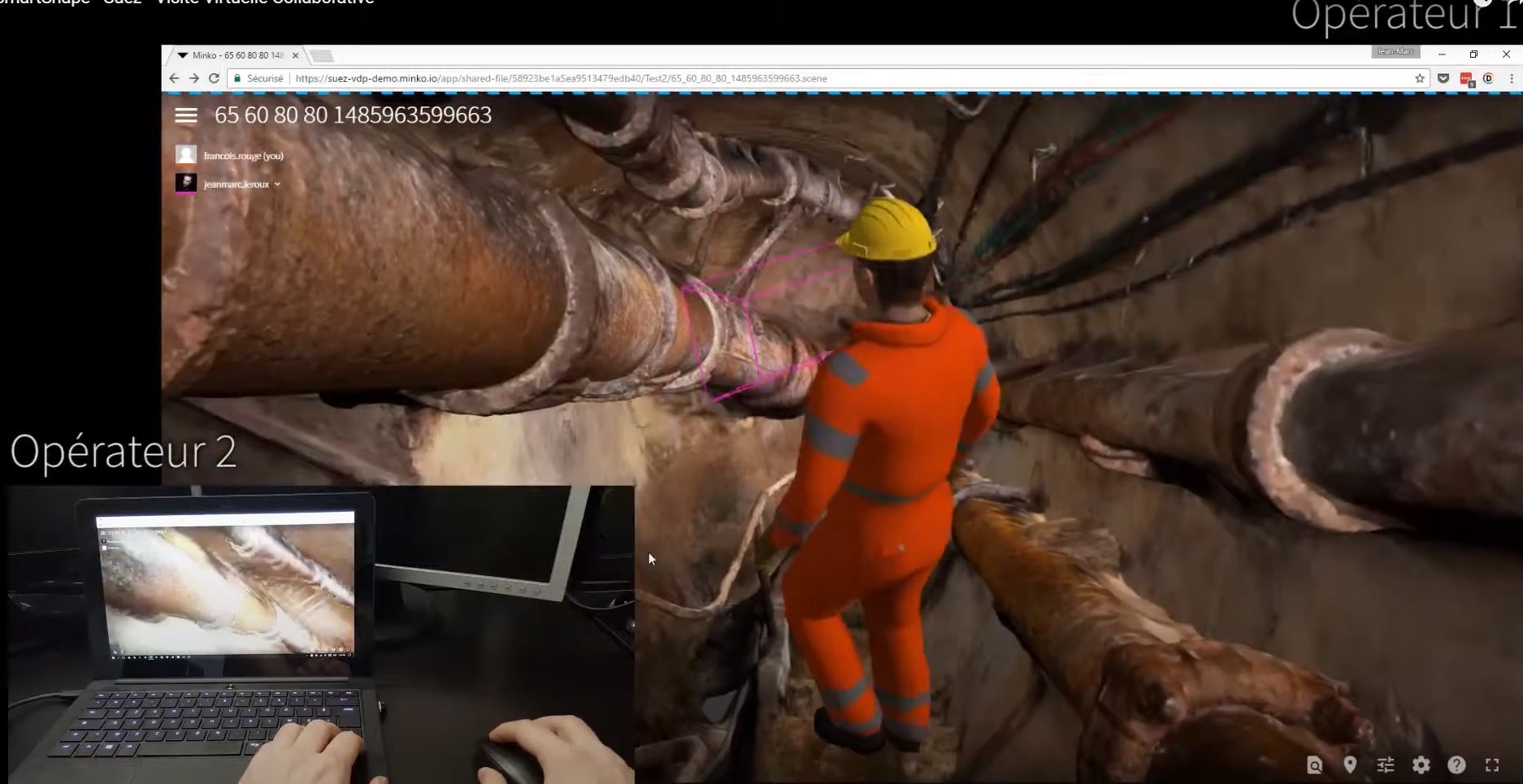

Collaborative virtual tour of the sewers

Before an intervention in the Parisian sewer network, operators have the ability to connect to the 3D model in SmartShape and conduct their virtual visit together. The avatar of the first operator appears on the screen of the second, and vice versa: they can see each other and follow each other in the 3D model as if they were on site. They identify potential risks and anticipate the tasks to be carried out to perform a safe and efficient intervention.

Collaborative features

“SmartShape provides operators with collaborative features to enrich the 3D model, which they can annotate during their virtual visit. Annotations appear in real time on the screen of each connected operator. Then, each annotation turns into a geo-referenced discussion within the 3D model: operators can enrich the model with their comments and ask questions.

Moreover, the annotations made by the operators are accessible for all subsequent visits. They can thus be used by the Technical Water and Sanitation Service (STEA) to establish safety instructions or to warn of a risk.

The demonstration carried out by SEMERU and SmartShape within the framework of the modeling project for the Paris city sewage network highlights the possibilities offered by the use of a 3D model within a collaborative platform. The result is unequivocal: professionals working in this network now have an effective and sustainable tool to help them accomplish their missions with limited risk.

Better understand the possibilities of SmartShape?

Schedule a demo