Unplanned downtime can be a significant drain on resources, costing industrial manufacturers billions annually. However, with advancements in technology, companies now have powerful tools to mitigate these losses. Digital twins, paired with artificial intelligence (AI), are transforming predictive maintenance, offering substantial cost savings and enhanced operational efficiency. This article delves into how these technologies, particularly those developed by SmartShape, are revolutionizing maintenance strategies across various industries.

Understanding Predictive Maintenance

Predictive maintenance is a proactive approach that involves monitoring the condition of equipment during normal operation to reduce the likelihood of failures. Unlike reactive maintenance (repairing after a failure) or preventive maintenance (scheduled based on time or usage), predictive maintenance aims to predict failures before they occur, thereby minimizing downtime and maintenance costs. However, traditional predictive maintenance faced challenges such as the high cost of sensors and data analysis limitations.

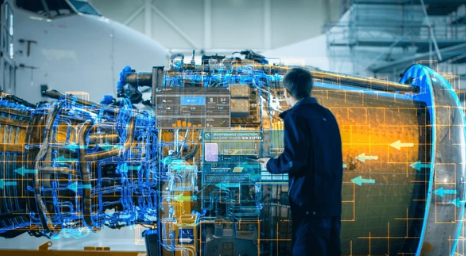

Introduction to Digital Twins

Digital twins are virtual replicas of physical assets, processes, or systems that allow for real-time monitoring and simulation. They consist of sensors that collect data, analytical tools that process this data, and simulation models that predict future performance. By creating a digital counterpart of a physical asset, companies can monitor conditions, predict outcomes, and optimize performance. Industries such as manufacturing, aerospace, and energy have started leveraging digital twins to enhance their operational capabilities.

SmartShape offers a robust digital twin solution that integrates seamlessly with various industrial applications, providing real-time insights and predictive analytics to optimize asset management and maintenance strategies.

Role of AI in Enhancing Digital Twins

Artificial intelligence plays a crucial role in maximizing the potential of digital twins. AI, particularly machine learning and advanced data analytics, can process vast amounts of data generated by digital twins. This integration allows for real-time analysis and decision-making, making predictive maintenance more accurate and efficient. AI algorithms can identify patterns and anomalies that human operators might miss, enabling proactive measures to prevent failures.

SmartShape’s platform leverages AI to enhance the capabilities of digital twins, offering advanced predictive maintenance solutions that are transforming industries.

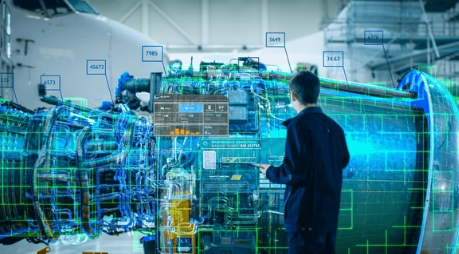

Case Studies and Real-World Applications

Manufacturing: A leading automotive manufacturer implemented digital twins and AI to monitor its assembly lines. Sensors installed on machinery provided real-time data, which AI analyzed to predict equipment failures. This approach reduced unplanned downtime by 20% and maintenance costs by 15%.

Energy Sector: In a power plant, digital twins of turbines and other critical infrastructure allowed operators to monitor performance continuously. AI analyzed data from various sensors to predict component failures and optimize maintenance schedules, enhancing operational reliability and efficiency.

Aerospace: Airlines have adopted digital twins and AI to maintain aircraft. By continuously monitoring engines and other critical systems, these technologies help predict maintenance needs, ensuring safety and reducing downtime. For instance, a major airline reported a 25% decrease in unscheduled maintenance events after implementing these technologies.

Benefits of Digital Twins and AI in Predictive Maintenance

Cost Savings: The primary benefit is the reduction in downtime and maintenance costs. By predicting failures before they occur, companies can schedule maintenance during non-critical times, avoiding expensive emergency repairs.

Operational Efficiency: Digital twins and AI provide detailed insights into asset performance, enabling better planning and resource allocation. This results in streamlined operations and improved productivity.

Safety and Reliability: Proactive maintenance enhances the safety and reliability of equipment, reducing the risk of catastrophic failures. This is particularly crucial in industries like aerospace and energy, where failures can have severe consequences.

For more information on the benefits of these technologies, visit SmartShape’s blog on optimizing operational efficiency.

Future Trends and Innovations

Emerging Technologies: Future advancements in IoT, edge computing, and enhanced AI algorithms are expected to further boost the capabilities of digital twins. These technologies will offer more precise predictions and more efficient maintenance strategies.

Industry Adoption: As the benefits of digital twins and AI become more evident, wider industry adoption is expected. However, challenges such as initial implementation costs and data integration need to be addressed.

Future Outlook: The future of predictive maintenance looks promising, with digital twins and AI at the forefront. These technologies will continue to evolve, offering even greater efficiencies and insights, ultimately transforming how industries manage and maintain their assets.

Digital twins and AI are revolutionizing predictive maintenance, providing significant cost savings, operational efficiencies, and enhanced safety. Companies across various sectors are starting to realize the potential of these technologies, which promise to reshape maintenance practices in the years to come. Embracing these innovations can lead to more reliable and efficient operations, paving the way for a future where downtime is minimized, and performance is maximized. For industries looking to stay competitive, the integration of digital twins and AI into their maintenance strategies is not just an option but a necessity.

For more insights and information on how SmartShape is leading the way in predictive maintenance, visit our blog and product pages.

Better understand the possibilities of SmartShape?

Schedule a demo