The naval industry, with its complex demands and technical challenges, is undergoing a significant digital transformation. Traditionally, naval projects have relied heavily on computer-aided design (CAD) tools, using 2D and 3D plans for ship modeling. While effective, these methods are now reaching their limits in terms of optimization, collaboration, and maintenance. In this evolving landscape, digital twins, powered by innovative solutions like SmartShape, are stepping in to redefine the industry’s standards.

From CAD to a Broader Vision

CAD has long been the cornerstone of naval design, enabling the creation of detailed models, but it remains a static tool. CAD models often require complex exchanges between different stakeholders, with the risk of inconsistencies or delays in information sharing. For shipyards, these inefficiencies can result in costly delays and resource misallocation.

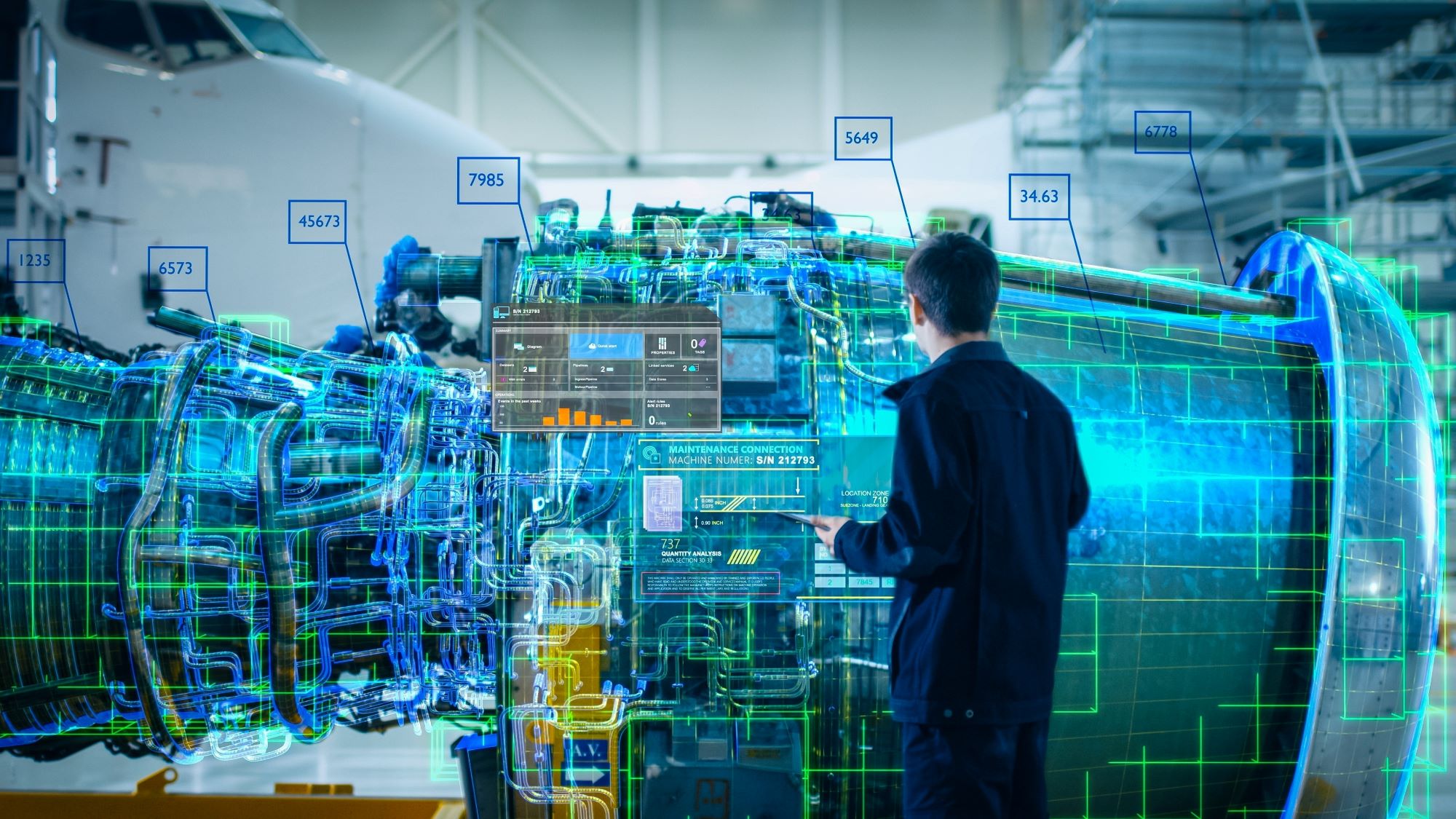

A digital twin, on the other hand, offers a dynamic and collaborative vision. More than just a 3D representation, a digital twin is a virtual replica connected to real-time data, integrating design, manufacturing, maintenance, and management processes. This evolving model centralizes all technical and operational information about a vessel in a shared space, accessible to all project stakeholders and updated in real-time.

Why Digital Twins Are a Game-Changer for the Naval Industry

The naval industry faces unique challenges, from building increasingly complex vessels to maintaining aging fleets. In this context, digital twins offer strategic advantages for several reasons:

- Enhanced Collaboration

Digital twins enable real-time collaboration between engineering teams, project managers, and shipyard operators. All stakeholders have access to a single source of truth, eliminating information silos. This leads to faster, more informed decision-making and reduces errors caused by outdated information. - Optimized Maintenance Processes

By integrating sensors and AI systems, digital twins facilitate predictive maintenance. They allow operators to anticipate breakdowns, optimize maintenance schedules, and reduce the downtime of vessels. Maintenance becomes proactive rather than reactive, directly improving operational availability. - Cost and Time Reduction

Offering an integrated and up-to-date view of every aspect of a project, digital twins help reduce construction and maintenance timelines. By identifying inconsistencies or design errors earlier in the process, they can be corrected before they have major impacts on the project. This translates to substantial savings in both time and money. - Increased Safety

By simulating different configurations or analyzing system performance under real conditions, digital twins help improve the safety of vessels and their crews. They also allow complex scenarios to be tested virtually before physical implementation, reducing risks.

SmartShape: Leading the Way in Naval Innovation

SmartShape is at the forefront of this digital transformation in the naval industry. Its digital twin solution not only replaces paper plans and CAD models with collaborative 3D virtual replicas, but also connects these models to intelligent systems and complex databases. With centralized and real-time management of information, SmartShape helps naval industry stakeholders streamline their processes, enhance the security of their operations, and improve overall efficiency.

The Future of Naval Industry is Digital

By leveraging digital twins, the naval industry is undergoing a true technological revolution. This shift to 3D, beyond basic CAD modeling, opens the door to major innovations in design, maintenance, and operations. With solutions like SmartShape, industry players now have the tools to meet the challenges of the future and increase their competitiveness in an increasingly demanding global market. Digital twins are no longer just a trend—they have become a necessity for the future of the naval industry.

Better understand the possibilities of SmartShape?

Schedule a demo